Marktronic BenchDot 4000

The large tabletop dot marker with comprehensive software and large marking area marks almost all plastics and metals. It is specially designed for 24/7 use and built accordingly robust.

The BenchDot 4000 is the logical further development of the Marktronic family. By using high-quality recirculating ball screws, double linear guides and bearing sets, the marking quality and reliability have been increased again without negatively affecting the robustness and durability.

A carbide stylus is set in vibration by a solenoid. This causes individual dots to be imprinted into the material, forming the marking. Almost all materials up to 62 HRC can be stamped. The surface can be smooth or uneven. The dotting machine can independently compensate for a height difference of 3 mm. Even hard-to-reach places can be marked with the BenchDot 4000.

The BenchDot 4000 consists of the marking head, a manual Z-axis with table, the control and the corresponding connection cable.

For special applications, appropriate fixtures up to fully automatic solutions can be designed and manufactured. Portable dot markers and built-in marking heads are also available as an alternative.

Technical data:

Control

- QWERTY membrane keyboard

- large and high-contrast display

- up to 1350 layouts can be stored

- USB connection

- 2 x RS232 connections

- digital I/O

Software

- character heights from 0.55 – 99.9 mm in 0.13 mm steps

- adjustable embossing force (thus also embossing depth)

- Different fonts

- Marking at any angle

- Marking in any radius

- Serial numbering

- 2D data matrix code

- Vector graphics and logo marking (.plt/.hpgl)

- Real time and date

- Mirror writing

- Password protection

- Test run function

- Various menu languages

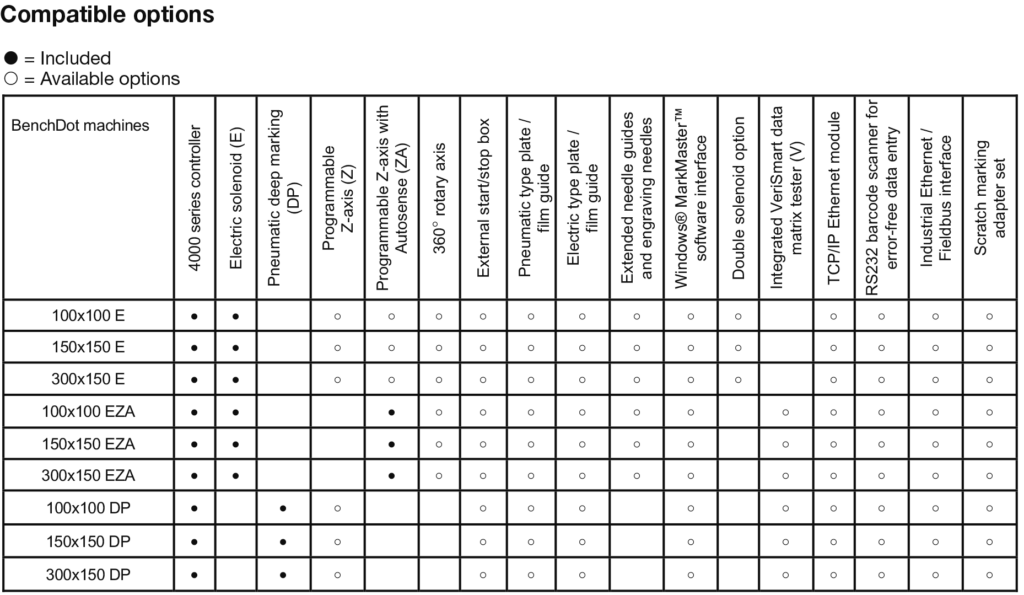

Options (at extra charge)

- different needle lengths: 50 mm, 100 mm or 150 mm

- different angles for the needles, also according to ASME-regulations

- Dividing head for radial marking on tubes or cylinders

- Electric Z-axis for automatic height adjustment

- Autosense, automatic distance detection workpiece-needle

- Pneumatic depth marking for very deep marking

- VeriSmart camera and software, immediate verification of the Data Matrix code after embossing

- TCP/IP Ethernet connection

- Windows software MarkMaster

- Magnet for clamping the workpieces

- Vice for clamping the workpieces

- T-slot plate

- Manual marking device

- Automatic embossing device with magazine

- Diamond scribe marking head (pneumatic)

Weight:

- Marking head with Z-axis and table 34 kg

- Control unit 10 kg

Power supply:

- 110 V – 230V

- 50Hz – 60Hz

Marking areas:

- 60 x 60 mm

- 100 x 100 mm

- 150 x 150 mm

- 300 x 150 mm