Description

Group 1705 3500

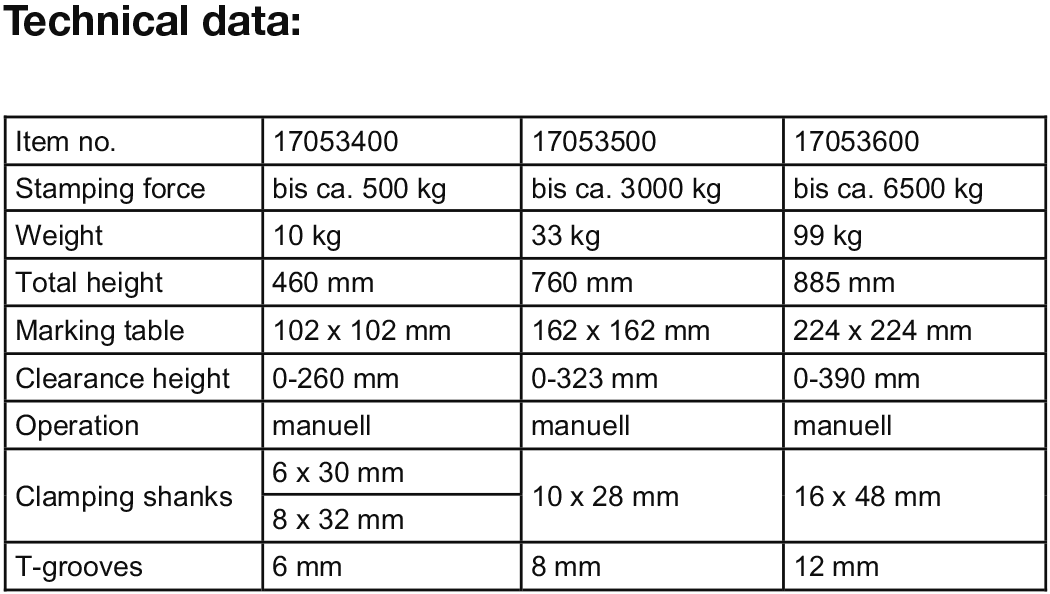

Universal spring-loaded impact press

In many branches of industry, operations such as stamping, straightening, deburring, riveting, punching, bending and flanging are carried out during the manufacture and further processing of workpieces. Some of these operations are still carried out by hand. For a modern rational working method, the use of spring impact presses is an option.

Working method:

A certain pressure is required for the operations described. In the presses shown, this pressure is generated by a spring in combination with a striker. The striker spring is tensioned to a certain point and released as required. In the process, the firing pin transmits the impact force to the clamped tool. In combination with the speed of the impact torque, large forces are generated. By adjusting the spring tension, the impact pressure achieved can be infinitely adjusted. The manual effort required is low, as the hand lever is only used to feed and clamp the tool. The effective working pressure is achieved by the special design of the spring impact press.

The spring impact press is equipped with four impact springs. This allows the force to be infinitely adjusted from 7 kN to 30 kN.

- Dimensions: 250 x 650 x 309 mm

- Adjustable stamping force: up to 30 kN

- Clearance height: 330 mm

- Weight: 33 kg

- Tool holder: 10 mm Ø x 30 mm

- T-slots: 10 mm (DIN 650)